custom beer bottle labels

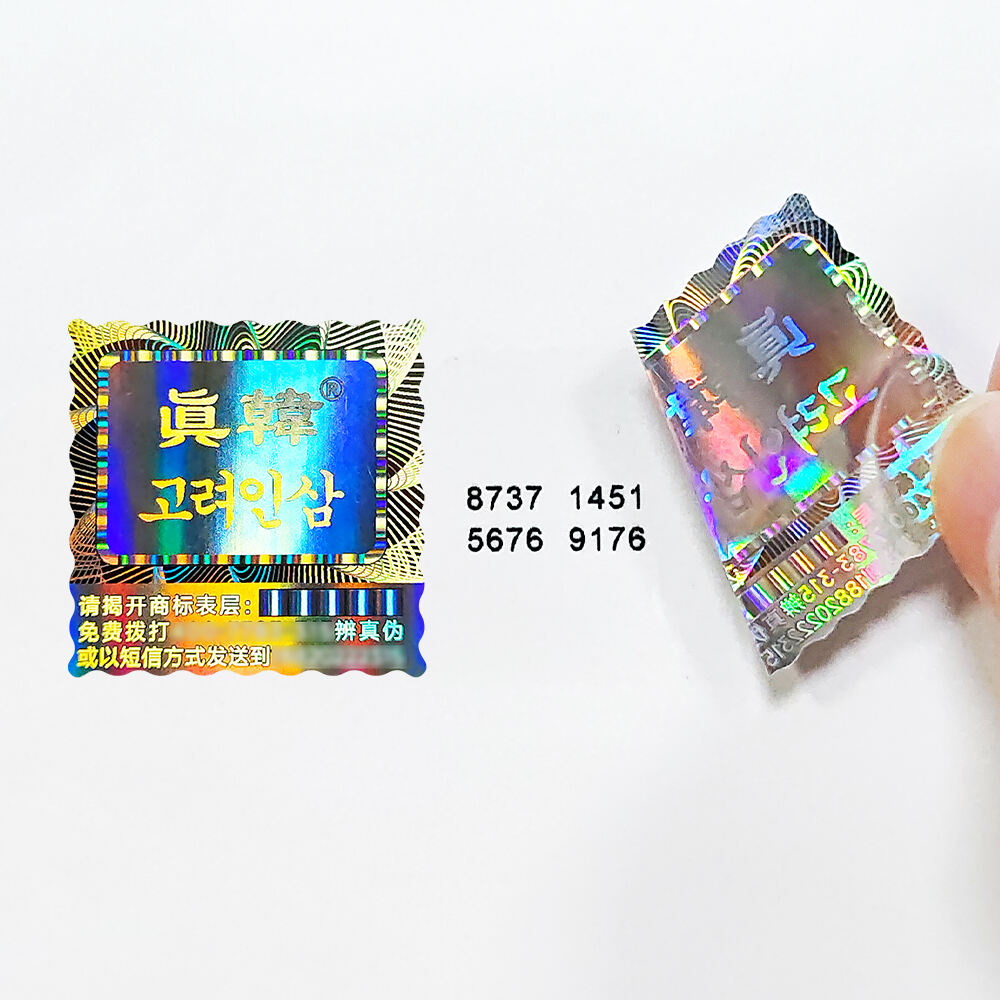

Custom beer bottle labels represent a vital component in craft brewing marketing, combining aesthetic appeal with functional necessity. These labels are engineered using advanced printing technologies and premium materials designed to withstand varying temperatures and moisture conditions typically encountered in beer storage and consumption. The labels incorporate waterproof adhesives and UV-resistant inks, ensuring longevity and maintaining visual appeal throughout the product's lifecycle. Modern digital printing techniques enable high-resolution graphics, metallic finishes, and textured elements that enhance shelf appeal. The labels can accommodate various bottle sizes and shapes, with options for wrap-around designs, neck labels, and specialty applications. Material choices range from premium papers to synthetic stocks, each offering different aesthetic and performance characteristics. These labels serve multiple functions beyond basic branding, including mandatory information display, batch coding capabilities, and tamper-evident features. Advanced production methods allow for small-batch runs with quick turnaround times, making them ideal for seasonal releases and limited editions. The labels can incorporate security features like holographic elements or QR codes for authentication and consumer engagement.