hologram sticker manufacturers

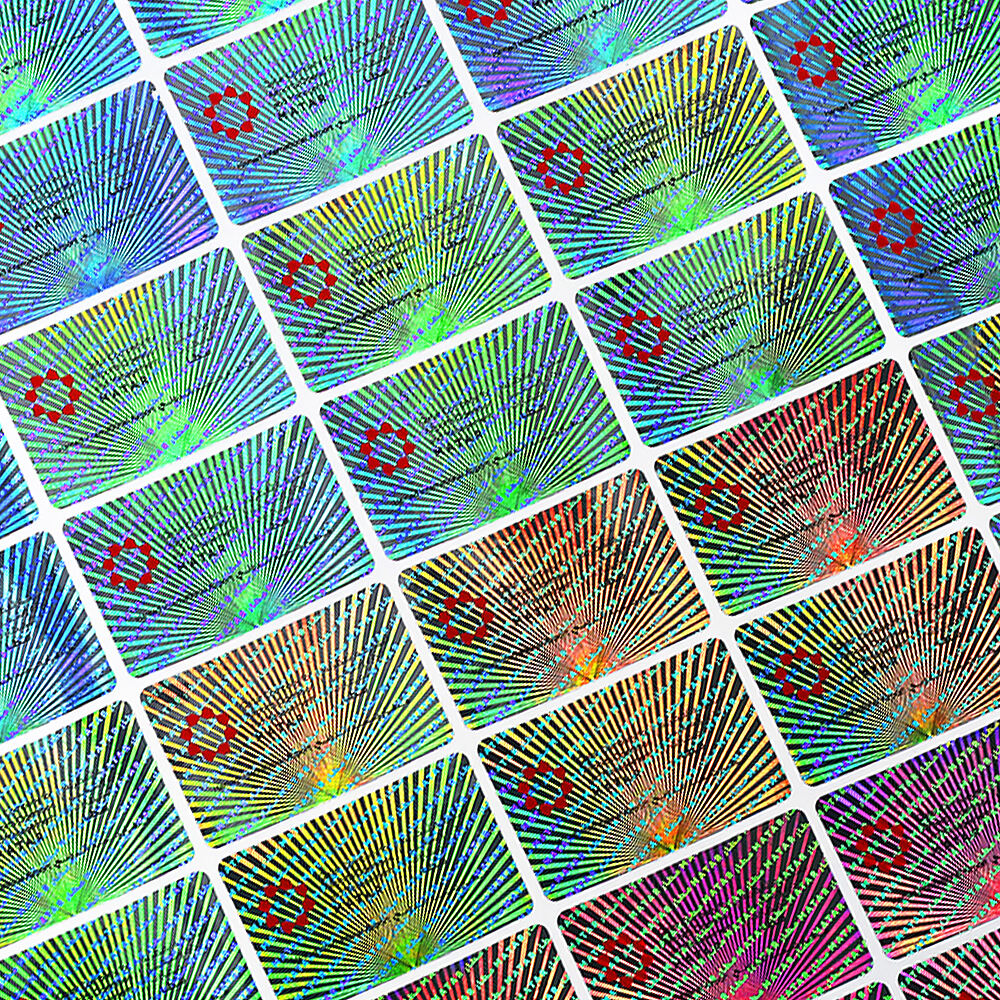

Hologram sticker manufacturers are specialized enterprises that produce advanced security labels incorporating cutting-edge holographic technology. These manufacturers utilize state-of-the-art equipment and precise manufacturing processes to create custom security solutions that protect brands and products from counterfeiting. Their production facilities typically feature clean rooms equipped with advanced optical systems, specialized coating equipment, and high-precision embossing machines. These manufacturers employ various techniques including dot-matrix holography, 2D/3D holography, and computer-generated holography to create unique visual effects. The manufacturing process involves multiple stages, from initial design and master hologram creation to mass production through embossing and coating. Modern hologram sticker manufacturers often integrate smart features like QR codes, track and trace systems, and tamper-evident properties into their products. They serve diverse industries including pharmaceuticals, electronics, luxury goods, and government security documents. Quality control measures are rigorously implemented throughout the production process, ensuring each hologram meets exact specifications and security requirements. Many manufacturers also offer customization options, allowing clients to incorporate specific security features, company logos, and unique identifiers into their holographic designs.