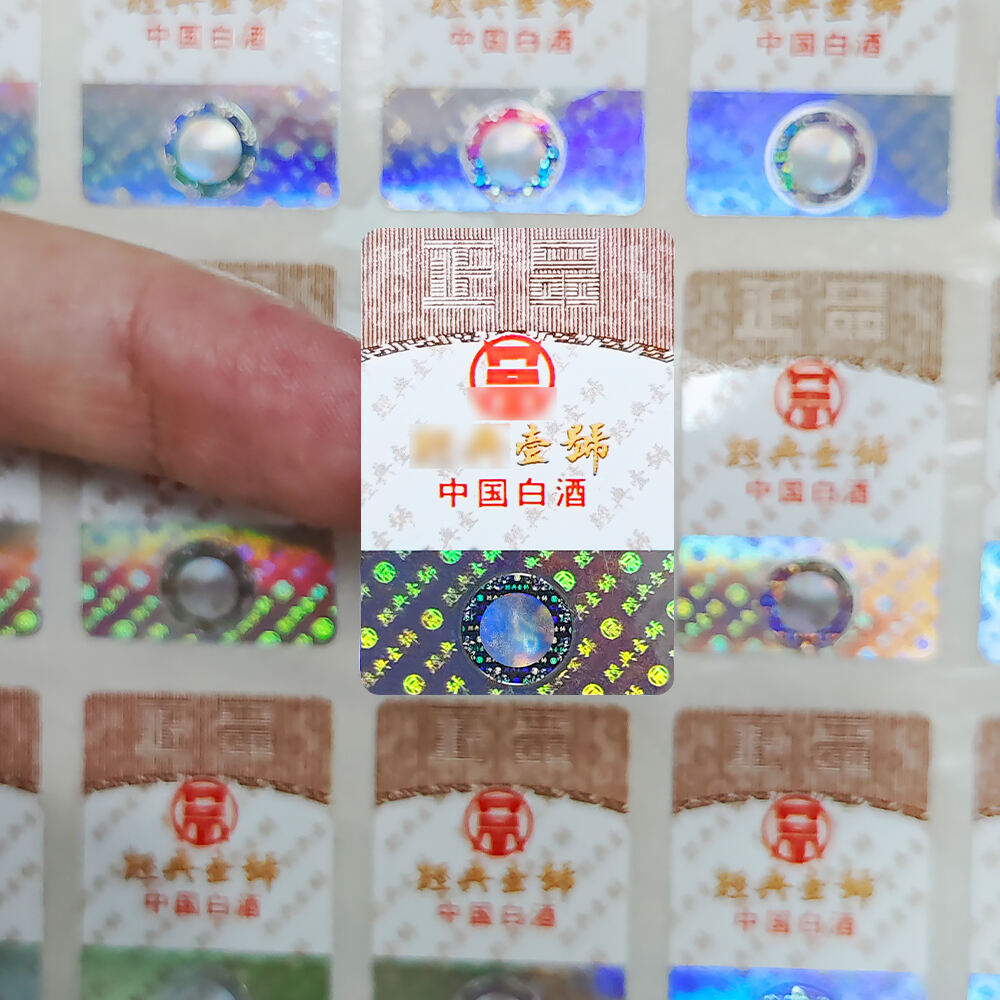

holographic labels manufacturer

A holographic labels manufacturer specializes in producing advanced security and authentication solutions using cutting-edge holographic technology. These manufacturers employ sophisticated equipment and processes to create multi-layered, optically variable devices that offer unique visual effects and tamper-evident features. The manufacturing process involves precision engineering, combining specialized materials with advanced printing techniques to produce labels that exhibit distinctive three-dimensional images, kinetic effects, and color-shifting properties. Modern holographic label production facilities utilize state-of-the-art laser technology, specialized coating systems, and high-precision embossing equipment to ensure consistent quality and security features. These manufacturers typically offer customization options, allowing clients to incorporate their brand elements, security features, and specific authentication requirements into the holographic designs. The production capabilities extend to various substrate materials, including metallic foils, polymers, and specialty papers, enabling versatility in application across different industries. Quality control systems and standardized production protocols ensure that each holographic label meets strict security and durability requirements, making them ideal for brand protection, product authentication, and anti-counterfeiting measures.