In today's competitive marketplace, businesses constantly seek innovative ways to enhance their product packaging and brand identity. Custom hot stamping hologram stickers have emerged as a powerful solution that combines security features with stunning visual appeal. These specialized adhesive products utilize advanced holographic technology and hot stamping processes to create eye-catching labels that not only protect against counterfeiting but also elevate brand perception. Understanding the design principles and manufacturing considerations behind these premium stickers can help businesses maximize their marketing impact while ensuring product authenticity.

Understanding Hot Stamping Hologram Technology

The Science Behind Holographic Effects

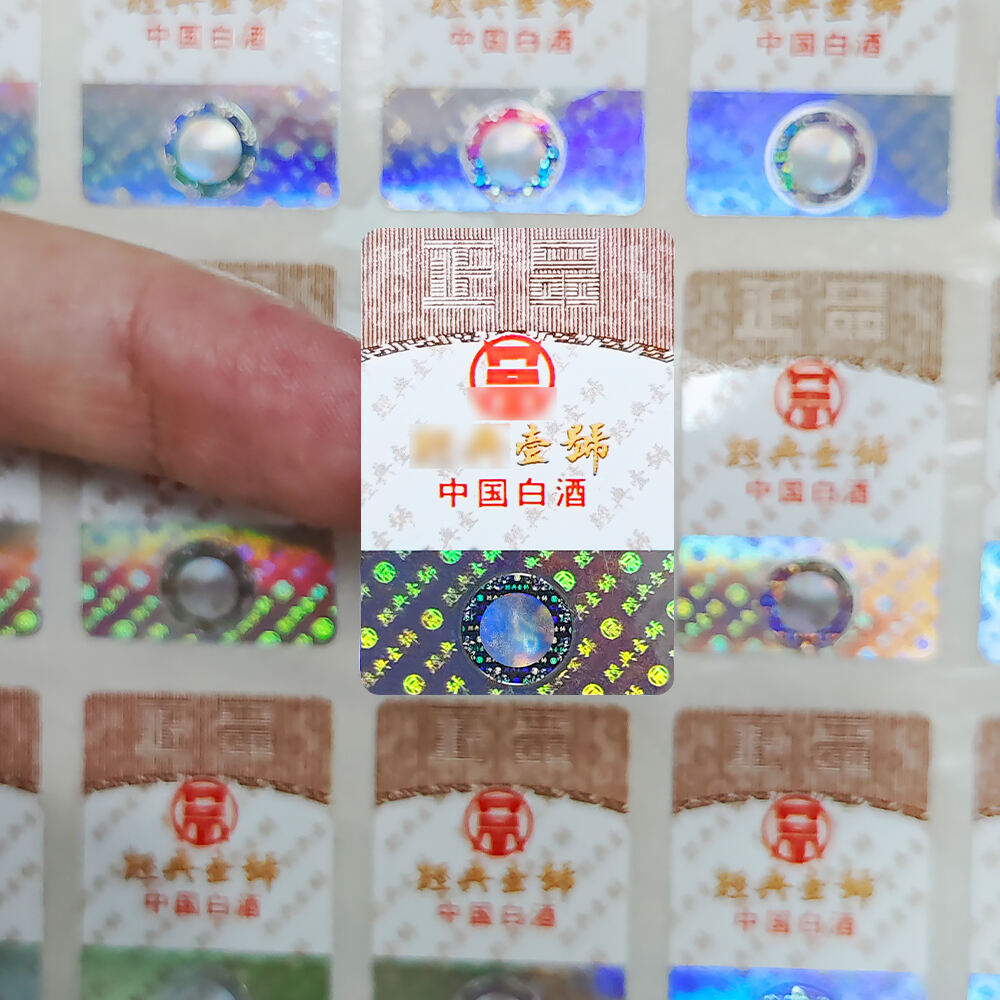

Hot stamping hologram technology combines traditional foil stamping with advanced holographic imaging to create three-dimensional visual effects. The process involves transferring metallic or holographic foil onto substrate materials using heat and pressure. This technique produces distinctive rainbow patterns, depth illusions, and shifting colors that are virtually impossible to replicate without specialized equipment. The holographic elements are created through laser interference patterns that manipulate light wavelengths, resulting in the characteristic prismatic effects that make these stickers so visually striking.

The manufacturing process begins with creating a master hologram using laser technology to record interference patterns on photosensitive materials. These patterns are then transferred to nickel shims through electroforming processes, which serve as the stamping dies for mass production. The precision required in this process ensures that each holographic element maintains consistent quality and visual impact across large production runs.

Material Selection and Substrate Compatibility

Choosing appropriate materials is crucial for achieving optimal results with hot stamping hologram applications. The substrate material must withstand the heat and pressure applied during the stamping process while maintaining dimensional stability. Common substrate options include polyester films, vinyl materials, and specialty papers designed for hot stamping applications. Each material offers different advantages in terms of durability, adhesion properties, and visual clarity.

The holographic foil selection equally impacts the final appearance and performance characteristics. Different foil compositions provide varying levels of brightness, color intensity, and environmental resistance. Premium foils incorporate multiple layers including release coats, color layers, holographic films, and adhesive systems that work together to ensure proper transfer and long-term performance.

Design Principles for Maximum Visual Impact

Color Psychology and Holographic Effects

Effective design of Custom Hot Stamping Hologram Stickers requires understanding how holographic effects interact with color psychology and brand messaging. The prismatic nature of holographic materials creates dynamic color shifts that can enhance emotional responses and increase memorability. Designers must consider how these shifting colors complement existing brand colors and messaging while ensuring readability across different viewing angles.

Strategic use of contrast between holographic and non-holographic elements helps direct viewer attention to key information. High contrast combinations ensure that text and logos remain legible even when holographic backgrounds create complex visual patterns. This balance between visual excitement and functional clarity determines the overall effectiveness of the sticker design.

Typography and Readability Considerations

Typography selection becomes particularly challenging when working with holographic substrates due to their dynamic visual nature. Sans-serif fonts generally perform better on holographic backgrounds because their clean lines maintain readability across different viewing angles and lighting conditions. Font weight and spacing must be carefully adjusted to ensure visibility against the shifting color patterns characteristic of holographic materials.

Text hierarchy becomes even more important in holographic applications where background complexity can overwhelm secondary information. Primary text elements should utilize sufficient contrast and sizing to maintain prominence, while supporting information may benefit from placement on solid color areas within the holographic design. This approach ensures that essential information remains accessible while maximizing the visual impact of the holographic effects.

Security Features and Anti-Counterfeiting Benefits

Authentication Elements Integration

One of the primary advantages of custom hot stamping hologram stickers lies in their inherent security features that help prevent counterfeiting and unauthorized reproduction. The complex manufacturing processes required to create authentic holographic effects make these stickers extremely difficult to replicate using standard printing equipment. This natural security barrier provides businesses with an effective tool for protecting their products and brand integrity.

Advanced security features can be integrated into the holographic design including microtext, sequential numbering, and tamper-evident properties. These additional elements create multiple layers of authentication that make counterfeiting increasingly difficult and expensive for potential fraudsters. The combination of visual verification and technical complexity provides comprehensive protection for high-value products and sensitive applications.

Tamper Evidence and Void Patterns

Tamper-evident properties can be engineered into custom hot stamping hologram stickers through specialized adhesive systems and substrate constructions. When removal is attempted, these stickers either leave behind residue patterns or self-destruct to clearly indicate tampering. This feature is particularly valuable for warranty seals, security labels, and applications where product integrity verification is critical.

Void patterns can be customized to display specific text or graphics when tampering occurs, providing immediate visual confirmation of unauthorized access. These patterns are created through careful engineering of the adhesive interface and substrate materials, ensuring reliable performance across various environmental conditions and application surfaces.

Manufacturing Process Optimization

Hot Stamping Parameter Control

Achieving consistent quality in custom hot stamping hologram stickers requires precise control of manufacturing parameters including temperature, pressure, and dwell time. Each substrate and foil combination requires specific parameter optimization to ensure proper transfer while avoiding damage to the holographic elements. Temperature control is particularly critical as excessive heat can distort holographic patterns while insufficient heat results in poor adhesion.

Pressure distribution across the stamping surface must be uniform to prevent variations in transfer quality that could compromise the holographic effect. This requires properly maintained equipment and careful attention to die preparation and alignment. Quality control systems should monitor these parameters continuously to maintain consistency across production runs.

Quality Assurance and Testing Protocols

Comprehensive quality assurance protocols ensure that finished custom hot stamping hologram stickers meet both visual and performance specifications. Testing procedures should evaluate holographic clarity, adhesion strength, environmental resistance, and security feature functionality. Visual inspection under controlled lighting conditions helps identify any defects in the holographic transfer or substrate preparation.

Accelerated aging tests simulate long-term environmental exposure to verify that holographic effects and adhesive properties remain stable over expected product lifespans. These tests help identify potential failure modes and optimize material selections for specific application requirements.

Application Techniques and Best Practices

Surface Preparation Requirements

Proper surface preparation is essential for achieving optimal adhesion and appearance when applying custom hot stamping hologram stickers. Target surfaces must be clean, dry, and free from contaminants that could interfere with adhesive bonding. Different surface materials may require specific cleaning procedures or primer applications to ensure reliable adhesion.

Surface texture and energy levels significantly impact adhesive performance and should be considered during the design phase. Smooth, high-energy surfaces generally provide the best results for holographic applications, while textured or low-energy surfaces may require specialized adhesive formulations or surface treatments to achieve acceptable performance.

Environmental Considerations and Durability

Environmental conditions during application and throughout the product lifecycle affect both the appearance and performance of custom hot stamping hologram stickers. Temperature and humidity levels during application can influence adhesive activation and initial bonding strength. Extreme conditions may require modified application procedures or specialized material selections.

Long-term exposure to ultraviolet radiation, moisture, and temperature cycling can gradually degrade holographic effects and adhesive properties. Understanding these environmental impacts helps in selecting appropriate materials and designing stickers that maintain their appearance and functionality throughout their intended service life.

FAQ

What makes custom hot stamping hologram stickers more secure than regular labels?

Custom hot stamping hologram stickers incorporate complex holographic patterns created through laser interference technology that requires specialized equipment and expertise to reproduce. The combination of hot stamping processes and holographic effects creates multiple security layers including visual authentication, tamper evidence, and technical barriers to counterfeiting that make these stickers extremely difficult to replicate using conventional printing methods.

How do environmental conditions affect the performance of holographic stickers?

Environmental factors such as temperature, humidity, and UV exposure can impact both the appearance and adhesive performance of holographic stickers over time. High temperatures may cause substrate expansion while UV radiation can gradually fade holographic effects. Proper material selection and protective coatings help minimize these effects, but understanding environmental exposure conditions is essential for optimizing sticker performance and longevity.

Can custom designs be integrated into holographic patterns without compromising security features?

Yes, custom designs can be successfully integrated into holographic patterns through careful design planning and advanced manufacturing techniques. Brand logos, text, and graphics can be incorporated as non-holographic elements or as part of the holographic pattern itself. The key is balancing visual impact with security functionality while ensuring that custom elements do not interfere with the authentication properties of the holographic features.

What are the minimum order quantities typically required for custom hot stamping hologram stickers?

Minimum order quantities for custom hot stamping hologram stickers vary depending on the complexity of the design, size specifications, and manufacturing requirements. Due to the specialized tooling and setup costs associated with holographic production, most manufacturers require minimum orders ranging from several thousand to tens of thousands of pieces. However, the exact quantity depends on specific design requirements and the manufacturer's capabilities and policies.

Table of Contents

- Understanding Hot Stamping Hologram Technology

- Design Principles for Maximum Visual Impact

- Security Features and Anti-Counterfeiting Benefits

- Manufacturing Process Optimization

- Application Techniques and Best Practices

-

FAQ

- What makes custom hot stamping hologram stickers more secure than regular labels?

- How do environmental conditions affect the performance of holographic stickers?

- Can custom designs be integrated into holographic patterns without compromising security features?

- What are the minimum order quantities typically required for custom hot stamping hologram stickers?