etita pūhā waina rorohiko

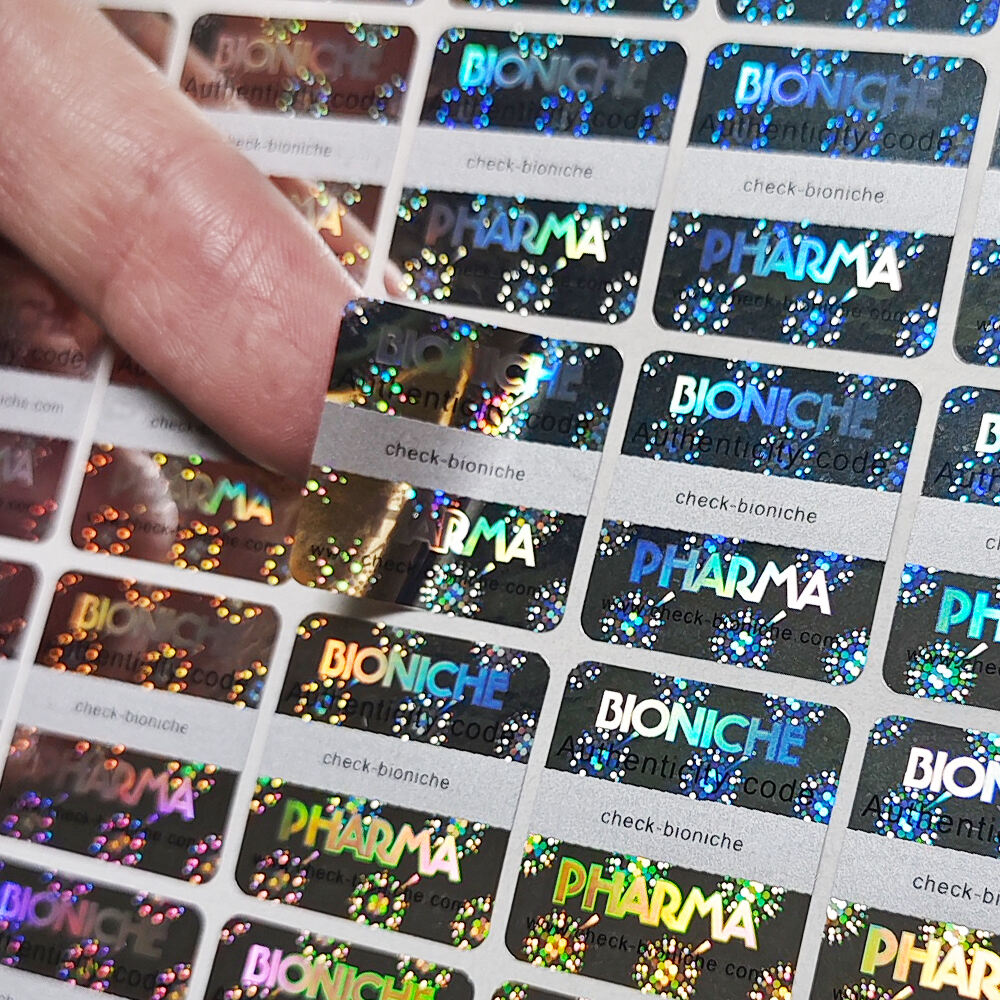

He momo whakawhitiwhiti kōrero iti ngā kape huka, he mea nui tonu i roto i te ao o ngā kape huka, e mahi ana i ngā tūtohu matua me ngā tūtohu ā-mata. Kua hanga ngā tūtohu kē ēnei hei whakarite i te pai ki ngā kape huka iti, e ahatia ana i waenga i ngā raupapa 187ml ki ngā 375ml. Kei raro i ngā tūtohu nei ngā hunga whakapai huaki mōhio, e tirotiro ana i te pūmau i runga i ngā wāhi taunga rerekē, ina whakarongo mai ki ngā hōngongo me te whakapau wai. E ai ki ngā tūtohu, kei raro i reira ngā horopaki tuhituhi pai rawa, e tautoko ana i ngā hanga mīharo, i ngā tahuhu kanohi, me ngā tae whakaahu, ahakoa ko te tino kitea i ngā kōrero nui, pērā i te tau hinga, te momo huka, me te panga hāpai. Kei te whakamahi ngā tūtohu hou nei i ngā whenua whakahirahira ka taea te whakahē i te kawe, te kawe kore, me te mate wai, kia mau tonu te kawe o te mana ki waho i te wā o te hiranga o te mea. Ka hanga i te pūnaha taiao-tika me ngā mahi tuhituhi whakatōpū, e whakaae ana ki ngā pātai taiao hoki, me te whakaae hoki ki ngā ture ao. Ko ēnei tūtohu ka whakauru anō i ngā whakaaetanga haumaru, pērā i ngā tau waehere kē ranei, i ngā QR codes hei whakamana me te whakapāpā. Kei te tino tino tūtohu ngā tūtohu nei, e taea ana te whakatakoto i ngā ata tika me ngā ata hou, e taea ana hoki te whakarite i ngā mana take rerekē me ngā tūtohu tūroa. He mea whakamaharatia ngā whakaritenga mo te kari o ngā kape iti, kia pai ai te whakatakoto, kia kaua hoki i te kōpiko ranei, i te kōkiri ranei i te whakapakari me te taunga.