lottery scratch factory

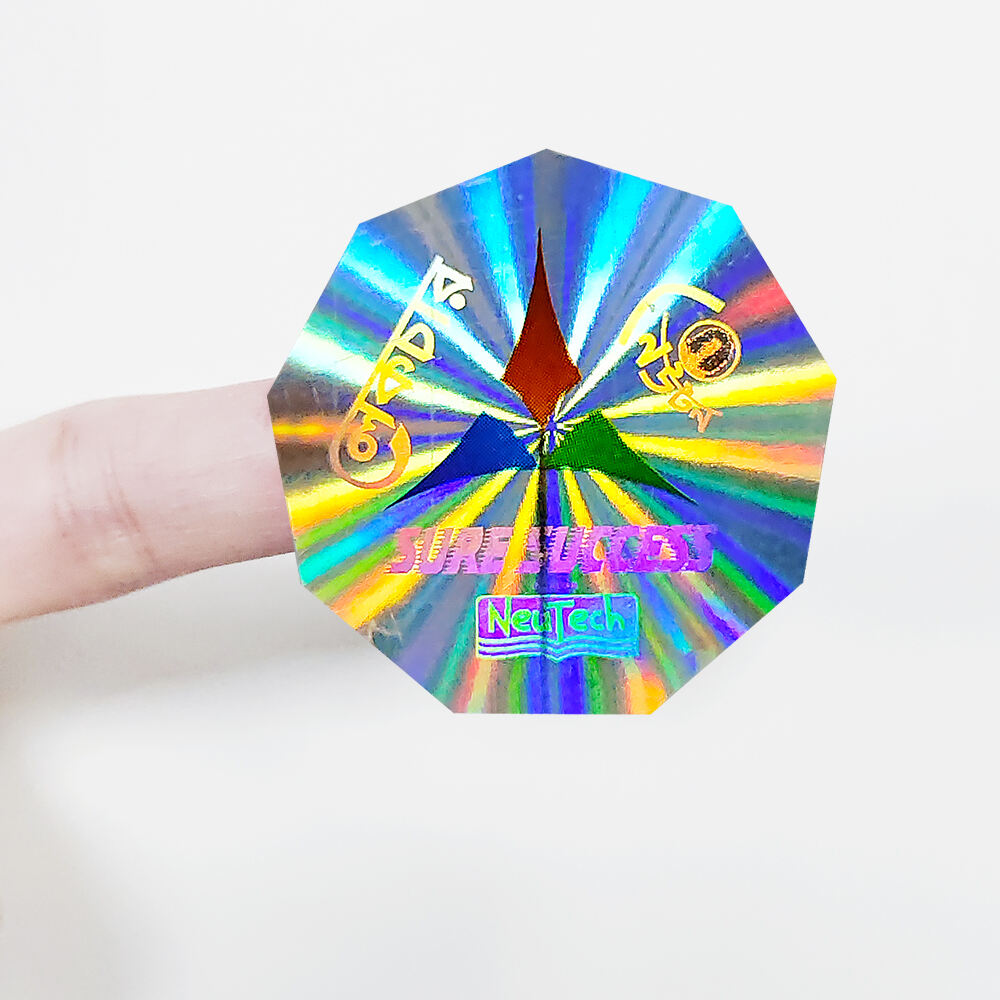

A lottery scratch factory represents a state-of-the-art facility dedicated to the production of instant lottery tickets, combining advanced printing technology with sophisticated security measures. These facilities utilize specialized equipment for applying scratch-off materials, implementing security features, and ensuring consistent quality across millions of tickets. The manufacturing process involves multiple layers of coating, including the base substrate, scratch-off material, overprint designs, and protective sealants. Modern lottery scratch factories employ computer-controlled systems for precise application of security elements, such as unique serial numbers, validation codes, and anti-tampering features. The production line incorporates high-speed printing capabilities, automated quality control systems, and real-time monitoring to maintain product integrity. Advanced imaging systems verify the accuracy of printed information and detect any defects before tickets leave the facility. These factories also implement strict inventory control measures and secure storage protocols to prevent unauthorized access to lottery products.