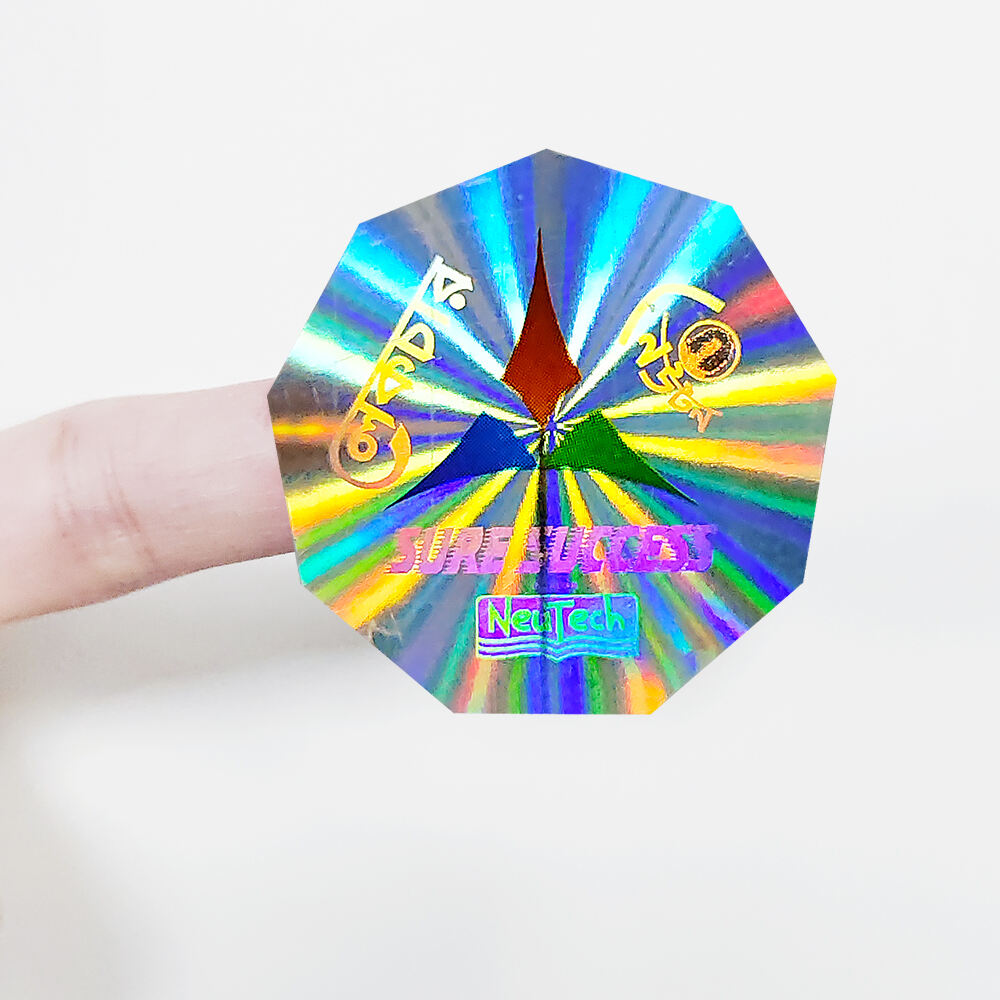

lottery scratch made in china

Lottery scratch products made in China represent a sophisticated blend of security features and innovative printing technology, designed to meet the global demand for reliable instant lottery games. These products utilize advanced manufacturing processes that incorporate multiple layers of scratch-off material, ensuring tamper-evident properties while maintaining excellent playability. The scratch-off coating consists of specialized latex-based materials that provide optimal coverage and a smooth scratching experience. Chinese manufacturers employ state-of-the-art printing equipment capable of producing intricate designs with high-resolution graphics and variable data printing, essential for unique game numbers and security codes. The production process includes rigorous quality control measures, incorporating UV-curable inks, specialized coatings, and multiple security features such as micro-printing and unique numbering systems. These lottery products undergo strict testing protocols to ensure consistency in scratch-off characteristics, durability, and resistance to various environmental conditions. The manufacturing facilities maintain ISO certification and adhere to international lottery security standards, making these products suitable for government-authorized lottery programs worldwide. The combination of competitive pricing, high-quality materials, and advanced security features has established China as a leading producer of lottery scratch cards in the global market.