Industrial-scale printing projects demand exceptional quality materials, and selecting the right hot stamping foil can significantly impact the final product's appearance, durability, and market appeal. Hot stamping foil represents a critical component in decorative printing processes, offering metallic finishes, holographic effects, and enhanced visual aesthetics that standard printing methods cannot achieve. Understanding the complexities of sourcing premium hot stamping foil requires comprehensive knowledge of material specifications, supplier capabilities, and application-specific requirements that align with industrial production demands.

Understanding Hot Stamping Foil Fundamentals

Material Composition and Structure

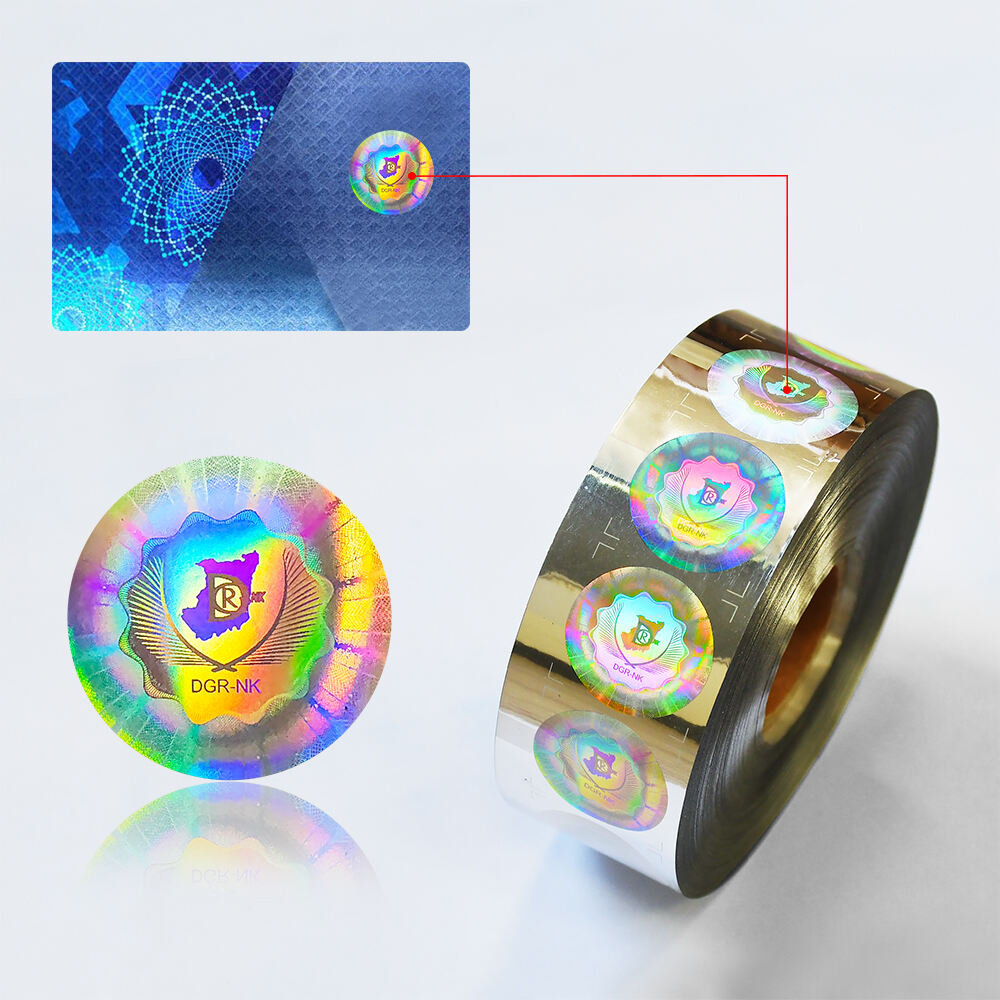

Hot stamping foil consists of multiple layers engineered to deliver specific performance characteristics under heat and pressure applications. The carrier film, typically made from polyester or similar materials, provides structural integrity during the stamping process. Release layers facilitate smooth separation from the carrier, while adhesive layers ensure proper bonding with target substrates. The decorative layer contains metallic particles, pigments, or holographic elements that create the desired visual effect when transferred.

Premium hot stamping foil incorporates advanced polymer chemistry to achieve consistent transfer properties across varying temperature ranges and substrate materials. Industrial applications require foils that maintain dimensional stability under high-volume production conditions while delivering uniform coverage and adhesion strength. Understanding these fundamental characteristics enables procurement professionals to evaluate supplier offerings effectively and select materials that meet specific project requirements.

Performance Specifications and Quality Standards

Industrial hot stamping foil must meet rigorous performance standards including temperature resistance, adhesion strength, and durability ratings. Temperature specifications typically range from 120°C to 200°C depending on substrate materials and processing equipment capabilities. Adhesion testing evaluates bond strength across different materials including paper, cardboard, plastics, and specialty substrates commonly used in industrial applications.

Quality standards encompass visual consistency, transfer efficiency, and resistance to environmental factors such as UV exposure, moisture, and mechanical stress. Premium suppliers provide detailed technical data sheets specifying these performance parameters, enabling buyers to make informed decisions based on measurable criteria rather than subjective evaluations.

Supplier Selection Criteria

Manufacturing Capabilities Assessment

Evaluating potential hot stamping foil suppliers requires thorough assessment of manufacturing capabilities, quality control systems, and production capacity. Leading suppliers operate specialized facilities equipped with precision coating equipment, environmental controls, and comprehensive testing laboratories. Production capacity considerations include minimum order quantities, lead times, and scalability to accommodate project growth or seasonal demand fluctuations.

Quality management systems should incorporate ISO certifications, statistical process control, and incoming material inspection protocols. Supplier audits provide valuable insights into operational procedures, equipment maintenance standards, and personnel training programs that directly impact product consistency and reliability.

Technical Support and Customization Services

Industrial projects often require customized hot stamping foil solutions tailored to specific applications, substrates, or visual requirements. Suppliers offering comprehensive technical support provide application engineering assistance, compatibility testing, and process optimization recommendations. Custom formulation capabilities enable development of specialized foils for unique applications including security features, specialty colors, or enhanced performance characteristics.

Collaborative relationships with suppliers facilitate continuous improvement initiatives and enable access to emerging technologies or advanced materials as they become available. Technical documentation, application guidelines, and troubleshooting resources contribute to successful implementation and ongoing operational efficiency.

Quality Control and Testing Protocols

Incoming Material Inspection

Establishing comprehensive quality control protocols begins with incoming material inspection procedures that verify hot stamping foil specifications against purchase requirements. Visual inspection identifies surface defects, color variations, or physical damage that could compromise transfer quality. Dimensional measurements ensure roll width, length, and thickness conform to specified tolerances.

Laboratory testing procedures evaluate critical performance parameters including release force, transfer temperature, and adhesion strength using standardized test methods. Documentation systems track material lots, test results, and acceptance criteria to maintain traceability throughout the production process.

Process Validation and Monitoring

Process validation establishes optimal operating parameters for hot stamping foil applications including temperature settings, pressure requirements, and dwell times. Statistical monitoring systems track key performance indicators such as transfer efficiency, defect rates, and substrate adhesion quality. Regular calibration of testing equipment ensures measurement accuracy and consistency over time.

Corrective action procedures address process deviations promptly to minimize waste and maintain production efficiency. Trend analysis identifies potential issues before they impact product quality, enabling proactive adjustments to maintain optimal performance standards.

Cost Optimization Strategies

Volume Purchasing and Contract Negotiations

Strategic procurement approaches for hot stamping foil include volume purchasing agreements that leverage economies of scale to reduce unit costs. Long-term contracts provide price stability and supply security while enabling suppliers to optimize production planning and inventory management. Negotiation strategies should consider total cost of ownership including freight, handling, storage, and quality-related expenses.

Supply chain optimization initiatives such as vendor-managed inventory programs can reduce carrying costs and minimize stockout risks. Collaborative forecasting improves demand planning accuracy and enables suppliers to provide competitive pricing based on predictable volume commitments.

Waste Reduction and Efficiency Improvements

Implementing waste reduction programs significantly impacts overall hot stamping foil costs through improved material utilization and reduced scrap rates. Process optimization studies identify opportunities to minimize setup waste, improve transfer efficiency, and extend die life through proper material selection and operating procedures.

Training programs ensure operators understand proper handling techniques, storage requirements, and application best practices that maximize material yield. Continuous improvement initiatives focus on identifying and eliminating sources of waste throughout the production process.

Application Considerations

Substrate Compatibility

Different substrate materials require specific hot stamping foil formulations to achieve optimal transfer quality and adhesion performance. Paper and cardboard substrates typically require lower temperature foils with aggressive adhesive systems, while plastic materials may need higher temperature formulations with specialized release characteristics. Surface preparation requirements vary significantly across substrate types and can impact foil selection decisions.

Compatibility testing protocols evaluate foil performance across the range of substrates used in production applications. Test procedures should simulate actual production conditions including temperature, pressure, and speed parameters to ensure reliable results that translate to operational success.

Equipment Integration

Hot stamping foil selection must consider compatibility with existing production equipment including stamping machines, heating systems, and feeding mechanisms. Equipment specifications determine maximum roll dimensions, core sizes, and unwinding characteristics that influence material procurement decisions. Operational parameters such as maximum line speed, temperature range, and pressure capabilities affect foil performance requirements.

Preventive maintenance programs ensure equipment operates within specified parameters to maintain consistent foil transfer quality. Regular calibration and adjustment procedures optimize performance and extend equipment life while maintaining product quality standards.

FAQ

What factors determine the optimal temperature for hot stamping foil applications

Optimal temperature selection depends on substrate material properties, foil formulation, equipment capabilities, and desired transfer quality. Most industrial applications operate between 140°C and 180°C, with specific temperatures determined through compatibility testing and process validation studies that evaluate transfer efficiency and adhesion strength across the operating range.

How can manufacturers ensure consistent quality when sourcing hot stamping foil from multiple suppliers

Maintaining quality consistency requires standardized specifications, comprehensive testing protocols, and supplier qualification programs that evaluate manufacturing capabilities and quality systems. Incoming inspection procedures, statistical monitoring, and performance tracking systems ensure materials meet established standards regardless of supplier source.

What storage conditions are recommended for preserving hot stamping foil quality

Proper storage conditions include temperature control between 15°C and 25°C, relative humidity below 60%, and protection from direct sunlight and contamination sources. Inventory rotation systems using first-in-first-out principles prevent aging-related quality degradation, while environmental monitoring ensures storage conditions remain within acceptable limits.

How does roll size affect hot stamping foil procurement and operational efficiency

Larger roll sizes typically provide better unit economics through reduced changeover frequency and lower packaging costs, but require compatible equipment capabilities and adequate storage facilities. Optimal roll size selection balances inventory carrying costs, changeover efficiency, and material handling requirements based on production volume and equipment specifications.

Table of Contents

- Understanding Hot Stamping Foil Fundamentals

- Supplier Selection Criteria

- Quality Control and Testing Protocols

- Cost Optimization Strategies

- Application Considerations

-

FAQ

- What factors determine the optimal temperature for hot stamping foil applications

- How can manufacturers ensure consistent quality when sourcing hot stamping foil from multiple suppliers

- What storage conditions are recommended for preserving hot stamping foil quality

- How does roll size affect hot stamping foil procurement and operational efficiency