The beauty industry faces unique challenges when it comes to product packaging and labeling, particularly in environments where moisture, humidity, and direct water exposure are common concerns. A waterproof cosmetic label represents a critical investment for beauty brands seeking to maintain product integrity, brand recognition, and consumer trust across diverse market conditions. These specialized labels ensure that essential product information, branding elements, and regulatory compliance details remain clearly visible and securely attached throughout the product's lifecycle, from manufacturing facilities to bathroom counters worldwide.

Understanding Waterproof Label Technology in Cosmetics

Advanced Material Compositions

Modern waterproof cosmetic labels utilize sophisticated material combinations that create impermeable barriers against moisture infiltration. These labels typically incorporate synthetic substrates such as polyethylene, polypropylene, or vinyl materials that naturally repel water molecules while maintaining flexibility and adhesion properties. The material selection process considers factors including temperature resistance, chemical compatibility with cosmetic formulations, and long-term durability under varying environmental conditions.

Premium waterproof labels often feature multi-layer constructions that combine protective topcoats, printed graphics layers, and specialized adhesive systems. The topcoat provides the primary moisture barrier while enhancing print quality and color vibrancy, ensuring that brand elements remain sharp and professional throughout extended exposure periods. This technological approach allows beauty brands to maintain consistent visual presentation regardless of storage conditions or consumer usage patterns.

Adhesive System Engineering

The adhesive component of waterproof cosmetic labels requires careful formulation to achieve permanent bonding while resisting moisture-induced degradation. Acrylic-based adhesives demonstrate superior performance in humid environments, creating molecular bonds that strengthen over time rather than weakening when exposed to water vapor or direct moisture contact. These adhesive systems must balance initial tack properties with long-term holding power to ensure labels remain securely positioned throughout product shelf life.

Temperature fluctuations present additional challenges for adhesive performance, particularly in international markets where products may experience extreme temperature variations during transportation and storage. Advanced adhesive formulations maintain consistent bonding strength across temperature ranges from freezing conditions to tropical heat, ensuring that waterproof cosmetic label applications remain reliable regardless of geographic distribution requirements.

Critical Applications in Beauty Product Categories

Skincare Product Requirements

Skincare products face particularly demanding labeling challenges due to their typical usage environments and formulation characteristics. Moisturizers, cleansers, and serums are frequently used in bathrooms where steam, splashing water, and high humidity levels create hostile conditions for traditional paper labels. Waterproof cosmetic labels ensure that ingredient lists, usage instructions, and expiration dates remain legible throughout the product's intended lifespan, supporting consumer safety and regulatory compliance simultaneously.

Premium skincare brands increasingly recognize that label durability directly impacts perceived product quality and brand reputation. Consumers associate label degradation with product deterioration, making waterproof labeling solutions essential for maintaining premium positioning in competitive markets. The ability to preserve crisp graphics and text clarity reinforces brand trustworthiness and supports premium pricing strategies across diverse retail environments.

Hair Care and Shower Products

Shampoos, conditioners, and styling products require waterproof labeling solutions due to their direct exposure to shower environments and frequent handling with wet hands. These products must maintain label integrity while subjected to steam, soap residue, and repeated water contact throughout their usage period. Waterproof cosmetic labels provide essential protection for regulatory information, brand elements, and consumer guidance that must remain accessible in challenging bathroom conditions.

Professional salon environments present additional labeling challenges where products experience frequent temperature changes, chemical exposure from other products, and intensive daily usage patterns. Waterproof labels ensure that professional stylists can easily identify products and access technical information even in busy, humid salon environments where multiple chemical products are used simultaneously throughout operating hours.

Manufacturing and Quality Control Considerations

Production Line Integration

Implementing waterproof cosmetic labels requires careful consideration of existing production line capabilities and labeling equipment specifications. High-speed application systems must accommodate the specific material properties and adhesive characteristics of waterproof labels while maintaining consistent placement accuracy and appearance quality. Production teams often need specialized training to optimize application parameters and troubleshoot potential issues related to material handling and adhesive activation.

Quality control protocols for waterproof labels typically include enhanced testing procedures that evaluate adhesion strength, moisture resistance, and print durability under accelerated aging conditions. These testing regimens simulate extended exposure periods and environmental stress factors to ensure that labels will perform reliably throughout product distribution and consumer usage phases. Comprehensive testing helps identify potential failure modes before products reach retail channels.

Regulatory Compliance Factors

Waterproof cosmetic labels must comply with stringent regulatory requirements regarding materials in contact with cosmetic products, adhesive migration potential, and long-term safety considerations. Regulatory agencies require extensive documentation demonstrating that label materials and adhesives will not contaminate product formulations or create safety risks for consumers during normal usage patterns. This compliance framework necessitates careful supplier selection and ongoing monitoring of material specifications.

International markets often impose additional requirements for label durability and information retention that make waterproof solutions particularly valuable for global beauty brands. Labels must maintain legibility for ingredient declarations, safety warnings, and usage instructions throughout product shelf life to meet regulatory standards in diverse jurisdictions. This requirement makes waterproof labeling technology essential rather than optional for brands seeking international market access.

Economic Benefits and Return on Investment

Brand Protection Value

Investing in waterproof cosmetic labels provides significant brand protection benefits that extend beyond immediate labeling costs. Products with deteriorated or illegible labels create negative consumer experiences that can damage brand reputation and reduce customer loyalty over time. Waterproof labels help maintain consistent brand presentation and product quality perception, supporting premium positioning and customer retention strategies that justify higher initial labeling investments.

Retail environments increasingly demand products that maintain attractive appearance throughout extended shelf periods and varying storage conditions. Waterproof labels help ensure that products remain shelf-ready and competitive-looking even after extended retail exposure, reducing the need for product rotation or markdown pricing due to appearance deterioration. This capability supports higher profit margins and stronger retail partner relationships.

Operational Efficiency Gains

Waterproof cosmetic labels reduce operational costs associated with product returns, customer complaints, and regulatory compliance issues related to label failure. Products with failed labels often require expensive remediation processes including relabeling, repackaging, or complete product replacement depending on the severity of label degradation. Waterproof labels minimize these operational disruptions while supporting consistent production scheduling and inventory management.

Distribution efficiency improves significantly when products utilize waterproof labels that remain intact and legible throughout complex supply chains involving multiple temperature zones, humidity levels, and handling processes. This reliability reduces the need for special packaging or storage requirements that can increase distribution costs and limit market accessibility for beauty products targeting diverse geographic regions.

Future Innovations in Waterproof Labeling

Smart Label Integration

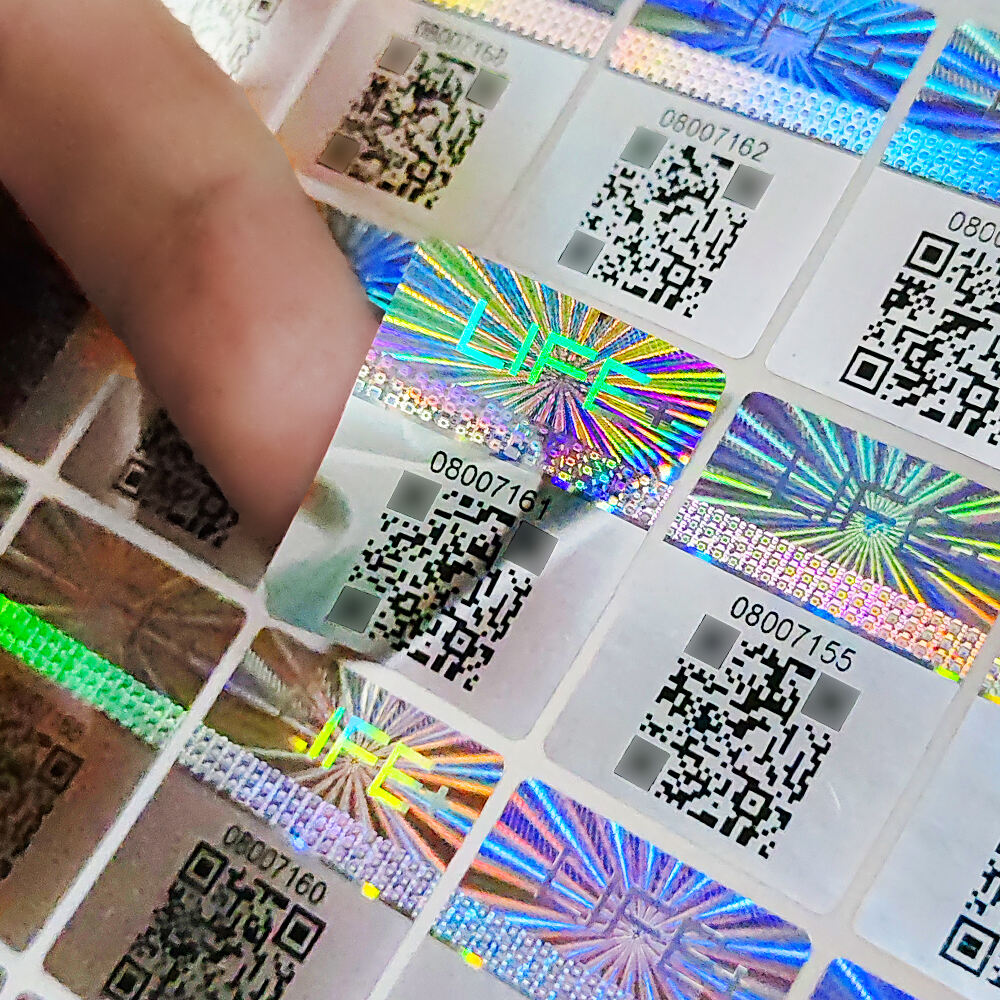

Emerging technologies are enabling the integration of smart features into waterproof cosmetic labels, including NFC chips, QR codes, and temperature-sensitive indicators that provide enhanced functionality while maintaining moisture protection. These intelligent labels can deliver personalized product information, authentication verification, and usage tracking capabilities that add value for both consumers and brand manufacturers. The combination of waterproof protection with smart functionality represents a significant advancement in cosmetic packaging technology.

Digital integration capabilities allow waterproof labels to serve as gateways to expanded product information, tutorial content, and brand engagement opportunities that extend beyond physical packaging limitations. This technological evolution enables beauty brands to create more interactive and informative consumer experiences while maintaining the essential protective functions that waterproof labels provide in challenging usage environments.

Sustainable Material Development

The cosmetics industry increasingly prioritizes sustainable packaging solutions, driving innovation in waterproof label materials derived from renewable sources or designed for improved recyclability. Advanced bio-based polymers and adhesive systems are being developed to provide waterproof protection while supporting circular economy principles and reducing environmental impact. These developments allow beauty brands to maintain performance requirements while addressing consumer demands for sustainable packaging options.

Recyclable waterproof label technologies are emerging that separate cleanly from containers during recycling processes, supporting comprehensive sustainability goals without compromising moisture protection performance. These innovations address the growing consumer and regulatory pressure for environmentally responsible packaging while maintaining the functional benefits that waterproof cosmetic labels provide for product protection and brand presentation.

FAQ

How long do waterproof cosmetic labels maintain their adhesion in high-humidity environments

Quality waterproof cosmetic labels typically maintain strong adhesion for 2-3 years in high-humidity environments when properly applied to clean, dry surfaces. The adhesive systems used in these labels are specifically formulated to resist moisture-induced degradation and actually strengthen over time through chemical cross-linking processes. However, adhesion duration can vary based on specific environmental conditions, substrate materials, and label quality specifications.

Can waterproof labels be removed cleanly from cosmetic containers for recycling purposes

Many modern waterproof cosmetic labels are designed with removable adhesive systems that allow clean separation from containers when heated or treated with appropriate solvents during recycling processes. Some labels feature specialized release coatings that facilitate removal, while others use adhesives that lose bonding strength when exposed to recycling facility cleaning solutions. However, removal ease varies significantly between different label types and adhesive formulations.

What testing methods verify waterproof label performance before commercial production

Standard testing protocols for waterproof cosmetic labels include immersion testing in distilled water at various temperatures, humidity chamber exposure at 85% relative humidity and 40°C, and freeze-thaw cycling to simulate temperature variations. Additional tests evaluate adhesion strength using standardized peel tests, print durability through abrasion resistance measurements, and chemical compatibility with common cosmetic ingredients. These comprehensive testing regimens ensure reliable performance under real-world usage conditions.

Are waterproof cosmetic labels compatible with all types of cosmetic packaging materials

Waterproof cosmetic labels demonstrate excellent compatibility with most common packaging materials including glass, various plastics, and metal containers. However, adhesion performance can vary on low-energy surfaces such as polyethylene or polypropylene without surface treatment. Optimal adhesion typically requires clean, dry surfaces free from oils, dust, or mold release agents that might interfere with adhesive bonding. Surface preparation and compatibility testing are recommended for challenging substrate materials.

Table of Contents

- Understanding Waterproof Label Technology in Cosmetics

- Critical Applications in Beauty Product Categories

- Manufacturing and Quality Control Considerations

- Economic Benefits and Return on Investment

- Future Innovations in Waterproof Labeling

-

FAQ

- How long do waterproof cosmetic labels maintain their adhesion in high-humidity environments

- Can waterproof labels be removed cleanly from cosmetic containers for recycling purposes

- What testing methods verify waterproof label performance before commercial production

- Are waterproof cosmetic labels compatible with all types of cosmetic packaging materials